Supply Chain Management Analytics offers more value than a Supply Chain Management Information System because it helps to optimize your business processes and answers questions that enable the business to analyze the past, optimize the present, predict the future and test core assumptions.

A very important question is the following : ‘Where does it make sense to apply Supply Chain Management Analytics in your company ?

It’s best to apply SCM Analytics to data-intensive business processes that are sub-optimized due to built-in constraints, such as lack of time, people, money,… SCM Analytics only makes sense when the business upside is big enough and the data complex enough to justify the costs.

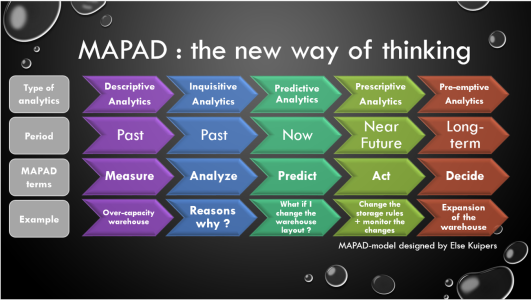

In the ‘Big Data’ Supply Chain Business world, we can detect also the 5 types of analytics (I’ve already mentioned in my blog about Retail Analytics) , namely :

- Descriptive analytics

- Inquisitive analytics (also mentioned as Diagnostic analytics)

- Predictive analytics

- Prescriptive analytics

- Pre-emptive analytics

Each type of those analytics contributes to the objective of improved decision-making. SCM Analytics makes it easier to uncover, anticipate and prevent potential risk factors. It can improve your supply chain performance by making everything more transparent and measurable, while exposing variability as well as potential issues and opportunities.

The SCM Analytics scheme :

Descriptive analytics (learn from past behavior to influence future outcomes) :

Descriptive analytics helps your company to understand what happened in the past. The past can be from one minute ago to a few days, a few weeks, a few months or a couple of years back. Descriptive analytics helps to understand the relationship between customers, carriers, suppliers and products and the goal is to gain an understanding of which approach to take in the future.

This type of analytics is an important source to determine what to do next. Descriptive analytics looks at data to describe the current situation in such a way that trends, patterns and exceptions become apparent.

Some examples of descriptive analytics :

- Reports

- Dashboards

- KPI-platform

- Management information system (MIS)

Inquisitive analytics (or Diagnostic analytics) :

We use this type of analytics to validate or to reject the different business hypotheses. Inquisitive analytics has to give an answer on the question : ‘Why did something happened at a certain moment in the past ?

Some examples of inquisitive analytics :

- Statistical analysis

- Factor analysis

Predictive analytics (about the future) :

Predictive analytics provides an estimation regarding the likelihood of a future outcome in your supply chain process, also it can help to identify some risks or opportunities in the future. Predictive analytics can be done by using a technique like :

No matter what, you still need business intelligence or in the terms of analytics, you still need descriptive analytics to know what really happened in the past, but you also need predictive analytics to optimize your processes and resources as you look to make decisions and take actions for the future. Predictive analytics takes the questions that descriptive analytics is answering to the next level, moving from a retrospective set of answers to a set of answers focused on process performance and prescribing specific actions or recommendations.

Prescriptive analytics :

With prescriptive analytics you try to see what the effect of future decisions will be in order to adjust the decisions before they are actually made. It provides advice based on the outcome of your predictive analytics.

An example of Prescriptive analytics :

- What – if analysis : what will happen when I change my process ?

Pre-emptive analytics :

Pre-emptive analytics is using to have ability to take preventive actions.